Quality and Safety Initiatives for Pigeon Products: Providing Customers with Safe and Reliable Products

Approach to Quality Assurance

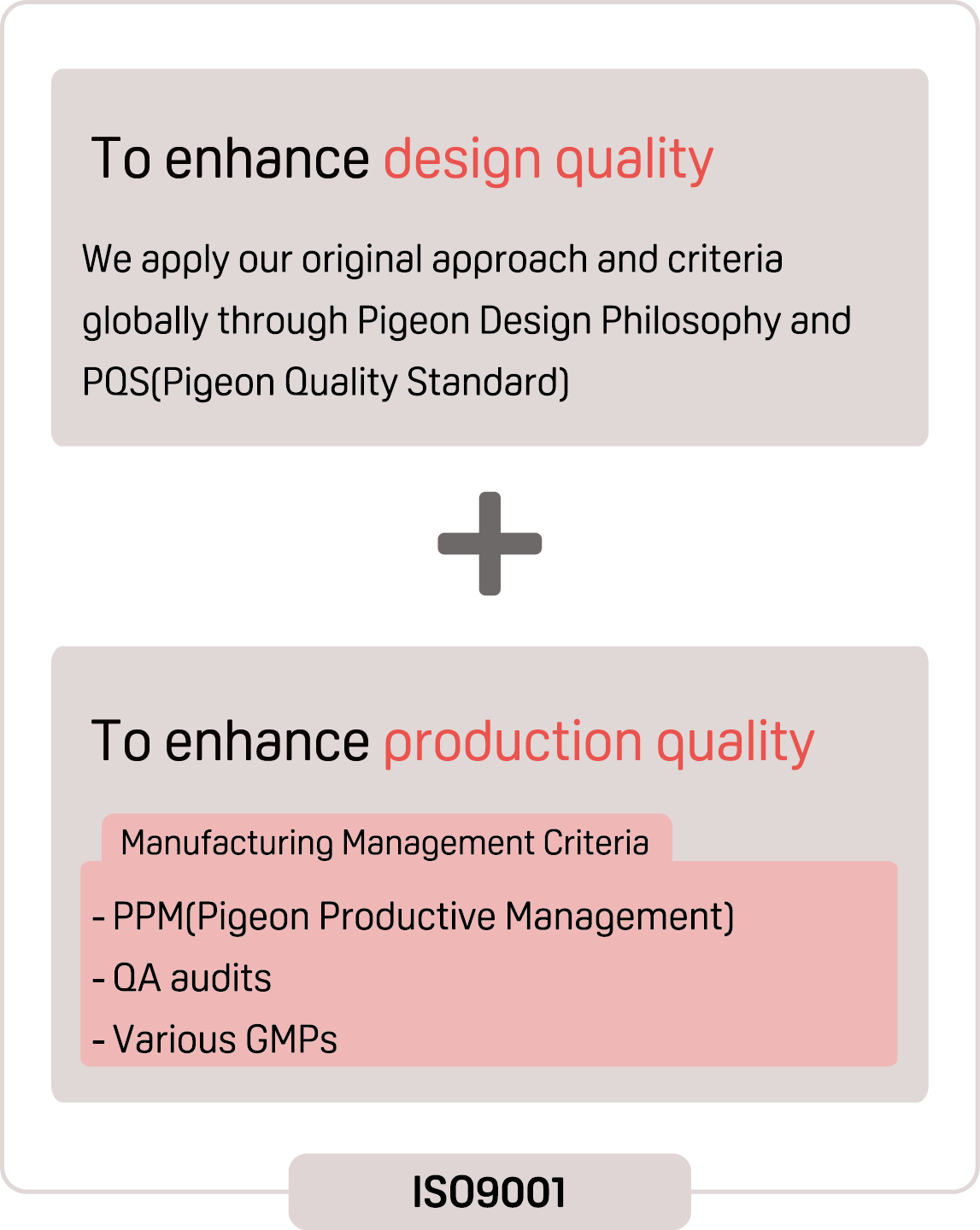

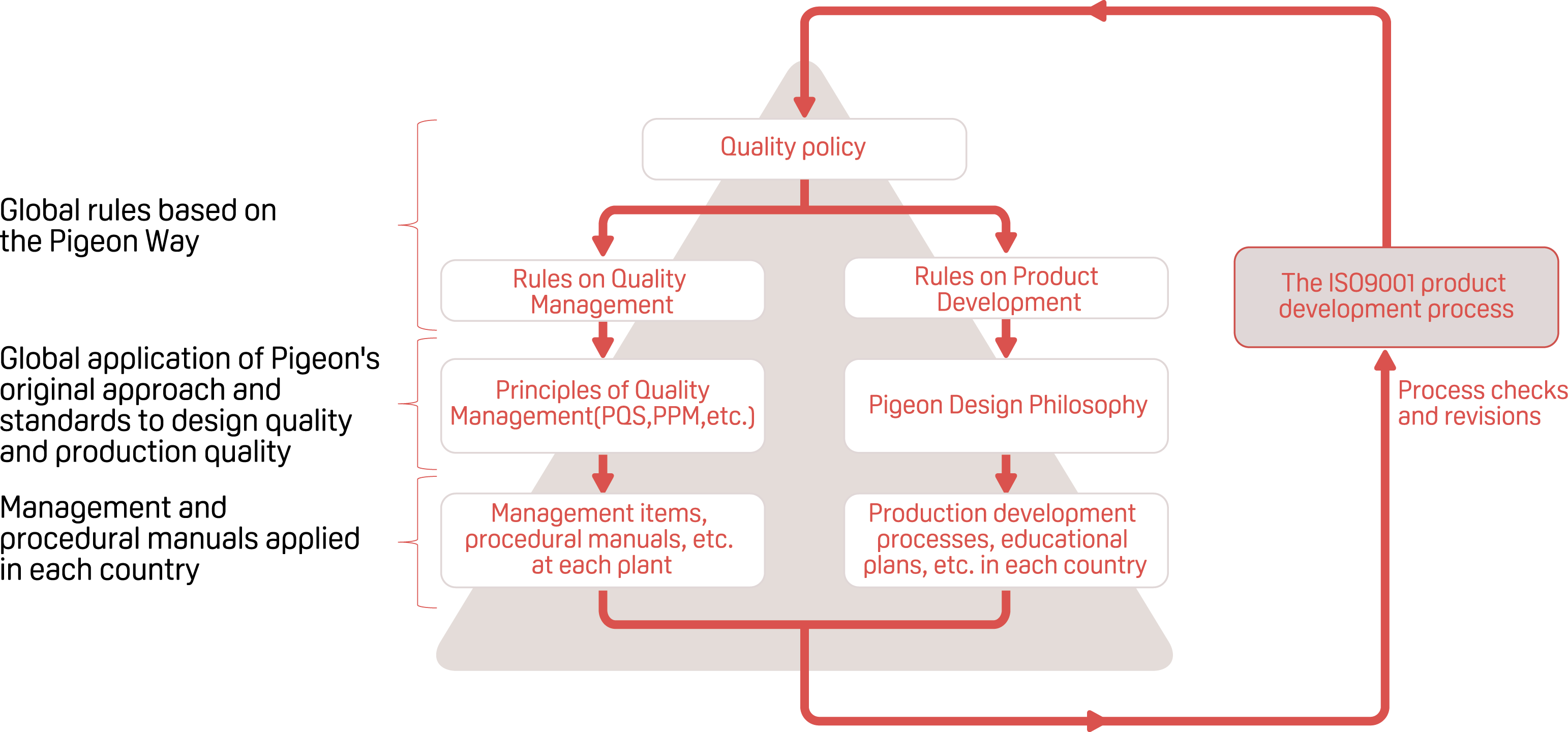

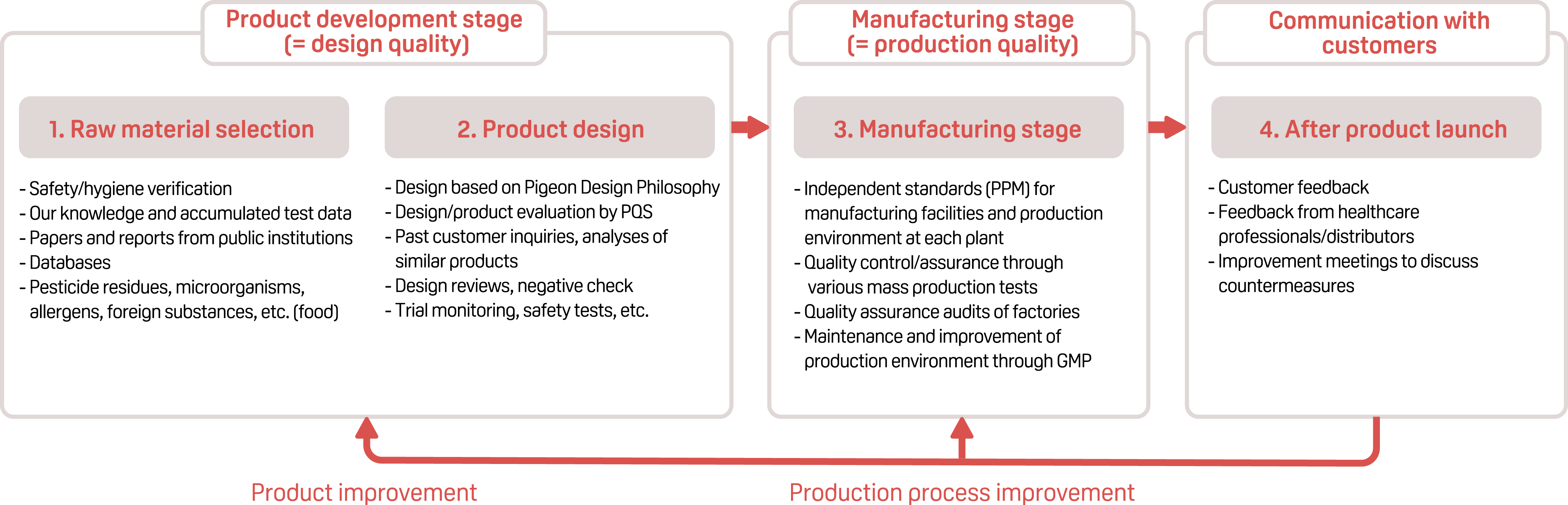

To deliver safe and reliable products to babies and their families around the world, the Pigeon Group is committed to improving product quality from two perspectives: design quality (at the product development stage, including the selection of raw materials and product design) and production quality (at the manufacturing stage). Both processes adhere to international ISO 9001 standards and are reviewed every six months. In addition, after product launch, customer feedback is shared to improve product design and manufacturing processes.

Quality Assurance System

Our Safety Criteria (for Safe Manufacturing)

Pigeon’s “Design Quality”

The Pigeon Group documents both the purpose of each product and the criteria for achieving that purpose in the Pigeon Design Philosophy, a living document that grows and evolves over time to reflect the vital ideas embodying our approach to product design. We have also established unique Pigeon Quality Standards (PQS) governing product safety, ease of use, and durability. By applying the Pigeon Design Philosophy and PQS globally, we are working to support and improve the design quality of our products manufactured worldwide.

From the product development stage, we select and use only raw materials confirmed to be safe, and at the development and design stage we conduct an in-house review process that includes design reviews and verifications of wide-ranging risks in various life scenarios (“negative check”). Through this review process, we predict and analyze potential risks in advance, such as defects, injuries, and accidents that could occur when using our products, and reflect them in our designs to prevent them from occurring in the first place. We also evaluate and verify design quality by using trial monitor tests to check whether developed products are of sufficient quality to meet customer needs and whether there are any points that need to be improved.

Pigeon’s “Production Quality”

Pigeon Productive Management (PPM) is an original set of criteria for the manufacturing equipment and production environments at each plant, and our products are manufactured only in plants that meet those standards. In addition to quality assurance (QA) audits at our production plants, which regularly check various aspects of our products, we strive to achieve stable quality by complying with the Good Manufacturing Practice (GMP) established for each country.

The system is designed to ensure that only products that have passed the inspection process, from incoming material inspection to in-process inspection during production and outgoing inspection of the final product, will be shipped. In the unlikely event of a manufacturing-related problem or a claim from a customer, we promptly provide feedback to the production department to determine whether the manufacturing process can be improved.

Connecting Customer Feedback to Quality Improvement

The Pigeon Group has a system in place to collect market information on launched products, including customer feedback and inquiries from medical institutions, and we reflect this information in our safety evaluations of raw materials and products. In the unlikely event of a safety concern, the relevant department holds a kaizen (improvement) meeting to determine the cause and promptly take necessary countermeasures. We always evaluate and verify our products from the consumer’s perspective and remain conscious of safety as we strive to maintain higher levels of quality.

Selection of Safe Raw Materials

Using guaranteed-safe materials to ensure peace of mind for customers and babies has always been a fundamental principle for Pigeon. We fully investigate the environmental impact of the products we create, and actively adopt more environmentally friendly materials in order to help create a future in which babies can thrive. To that end, we continuously gather information and maintain ongoing contact with government bodies, academia, and related industries.

Products Such as Nursing Bottles and Pacifiers

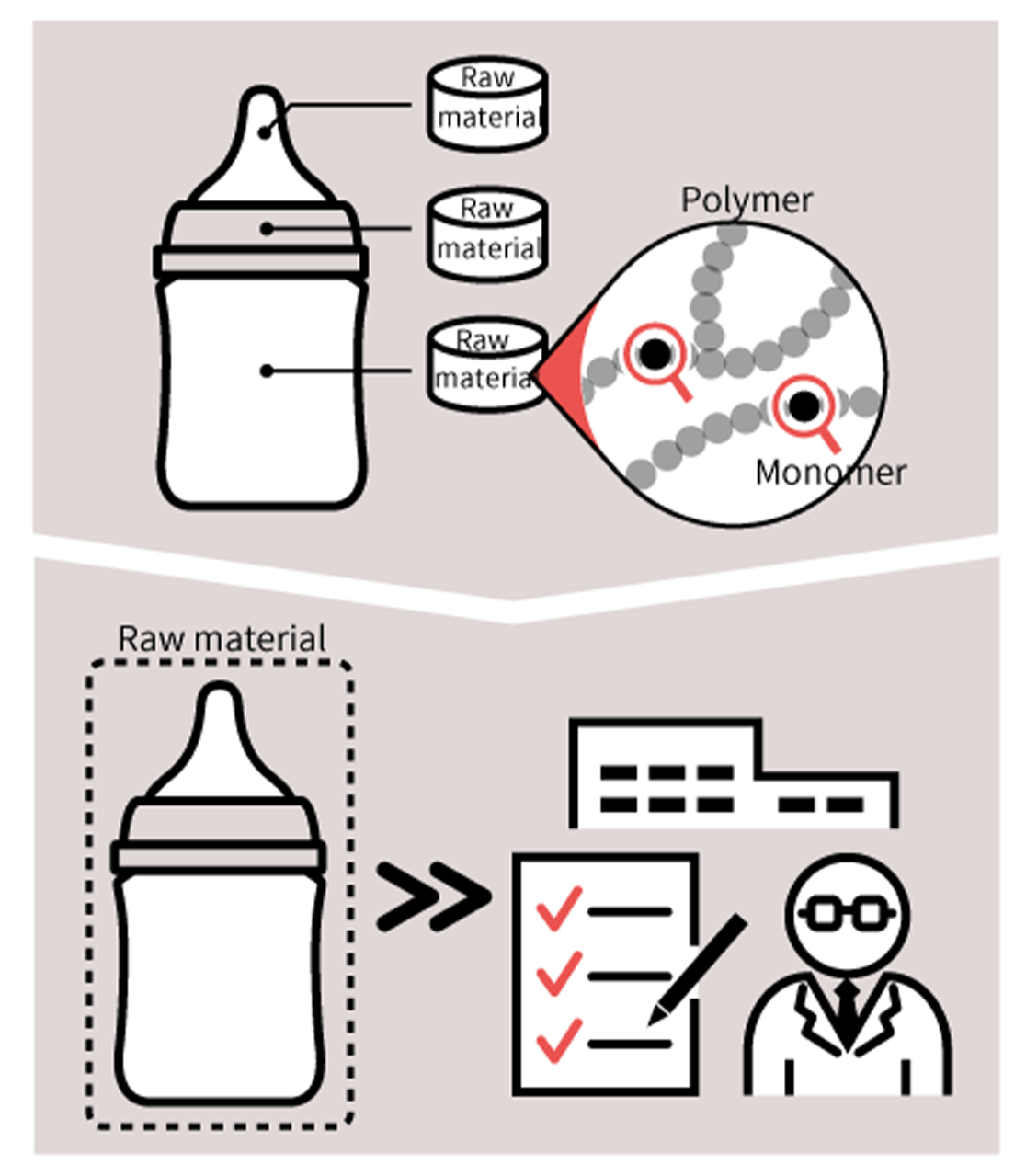

When selecting raw materials for use in nursing bottles, pacifiers, and other products intend for babies, we adhere strictly to our own unique and high standards for safety.

Babies have a tendency to lick or put in their mouth anything they can reach. Accordingly, when designing any product that might find its way into a baby’s mouth, we test candidate materials for safety using the same standards we apply for products designed for oral use, like utensils and pacifiers.

Our materials selection process begins with an investigation that draws on chemical materials databases available domestically and internationally to identify potential harms.* We check the safety not only of materials like plastic and rubber, but also of the components in those materials (monomers, additives, and so on).

The next step is to have our tentatively selected materials examined by external bodies, in accordance with international standards and the requirements of the intended countries of sale. Only materials that pass these examinations are used in products.

These procedures ensure that all our raw materials meet strict standards, so that customers can use our products with the peace of mind that is all the more important when babes are involved.

* Carcinogenicity, mutagenicity, reproductive toxicity, endocrine disruption, etc.

Skincare Products, Shampoos, etc.

For skin care products, laundry detergents, cleaners, disinfectants, and similar products, we not only strictly adhere to the regulations of the intended countries of sale, we also ensure safety by gathering safety information from a wide variety of internal and external sources about the components to be included, evaluating our findings in light of the quantities involved and how the product will be used.

When selecting components, along with ensuring the absence of harms such as primary skin irritation, sensitization, and eye irritation,* we also make use of a wide variety of information sources to survey and consider safety risks. These sources include histories of component use both inside and outside Pigeon, internally accumulated evaluation and testing data, academic papers and reports from public entities, and databases.

Industrial raw materials can also include additives called carryover components** to maintain materials quality. We ensure that we understand the makeup of any carryover components and check them for safety risks in the same way.

* The potential harms we evaluate for are not limited to these three items. Examinations and checks are also carried out with consideration for the characteristics of the components and products.

** Carryover components are additives included to maintain the quality of materials and components which do not have any potency or effect once the material has been made into a product because they remain in only trace quantities. For example, preservatives and antioxidants added to preserve components are carryover components.

Product Design and Safety Confirmation

At the development and design stages, we conduct an in-house review process that includes design reviews and verifications of wide-ranging risks in various life scenarios (“negative check”) to predict and analyze potential risks that may arise when products are in actual use, such as misuses, injuries and accidents. We then build measures against these risks into our product designs.

We evaluate and test design quality using experimental monitor tests. These tests examine whether products under development are built with the necessary quality to meet customer needs and whether improvements are needed.

Nursing Bottles, Pacifiers, etc.

In the development process, we verify safety through our own in-house review system, which includes design reviews. We also conduct comparative analyses and trial monitoring tests with competing and similar products to prevent product defects, and we perform multifaceted, objective evaluations of usability. These tests enable us to perform multifaceted, objective evaluation of measures to prevent any types of failures and the feeling of using each product. By applying product design according to PQS across its global platform, we work hard to support and improve the design quality of the products it sells in countries worldwide.

Skincare Products, Shampoos, etc.

In verifying the safety of our products, we conduct various evaluation tests, including those using cells and skin models, tests of the product on human skin (human patch tests), component analyses to confirm absence of harmful ingredients, and aging tests to confirm changes in properties over time. We also take into consideration the conditions in each sales region. In addition to these, we use an in-house review process that includes design reviews to reflect the details of previous customer inquiries into products. Also, experimental monitor tests are used to examine function and uncover points for improvement, thereby confirming design quality.

During Product Manufacturing

Our products are manufactured only at plants that satisfy the manufacturing environment stipulated by us. We regularly conduct quality assurance (QA) audits of production sites from a variety of angles, to uphold quality at each plant.

Products manufactured at these sites are tested at every stage. Only products that pass inspections from acceptance inspection of materials to process inspection during production and shipping inspection of the final product are shipped to customers.

In the event that a customer reports a problem originating in the manufacturing process or make a request, feedback is immediately provided to the production side. Manufacturing processes are then examined to determine whether corrections can be made.

Communication with Customers (After Product Launches)

Once a product is launched, we gather market information (such as feedback from customers and inquiries from medical facilities). We then build a framework for reflecting that information into safety evaluations of materials and products.

In the event that a suspected safety problem arises, the related sectors hold review meetings (kaizen meetings) to elucidate the causes of the problem and devise necessary countermeasures in a timely manner.

At the Pigeon Group, safety is always uppermost in our minds. The Group evaluates and tests its activities from the customer’s perspective, supporting safety and quality at exacting levels.

Approach to Risk Management of Chemical Substances

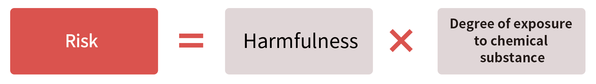

Chemical substances enrich our lifestyles and are essential for convenient and comfortable living. In the raw materials and products available in the market, it is said that there are tens of thousands of different chemicals in various forms. Some of those chemical substances pose the risk of impact on the environment or human health. The extent of that risk depends on the inherent harmfulness of the chemical substance in question and the degree of exposure.

To ensure that customers can use our products with peace of mind, Pigeon not only strictly adheres to relevant laws and regulations, it also selects low-risk raw materials based on its own Principles of Quality Management. We also pursue management for chemical substances by periodically surveying the chemicals included in products, controlling the chemicals emitted from plants, and providing safety data sheets (SDS) for transport.

Our Policy on Animal Testing

The Pigeon Group recognizes the movement to eliminate animal testing as a vital global demand. We are undertaking an array of measures aimed at achieving the elimination of animal testing.

We never conduct tests using animals in the development of skin care products and never permits its outside contractors to do so. Moreover, hawse have no plans to conduct or permit such tests in the future1.

We use original criteria to secure the safety of its skin care products. Our approach is to use the knowledge about safety we have accumulated on various formulations and ingredients from previous development activities and to conduct tests on substitutes for animal testing and other solutions.

On substitutes for animal testing, we continuously collect information in partnership with industry organizations, academic societies and other companies, in Japan and overseas. In this way we actively adopt testing methods of high reliability listed in international testing guidelines.

1: This statement does not include cases where such testing unavoidable due to a duty to explain product safety to the public or government mandating of testing in certain countries. Even when we conduct animal testing in these unavoidable circumstances, we make every effort to minimize animal testing based on the basic philosophy of the three Rs of tender care: Replacement, reduction, refinement.